|

Wind turbines are located in open spaces often in rocky mountainous areas where soil resistivity is high making them particularly vulnerable to lightning currents that may threaten human life or damage expensive equipment.

Partnered with surge protection devices (SPD’s), a low resistance path to earth is the most important factor in providing protection for both personnel and equipment. The best SPD’s available will fail to offer the required protection if grounding resistance is high, but designing an effective grounding system for single turbines or entire windfarms in a high resistivity environment or where space may be limited poses a serious challenge.

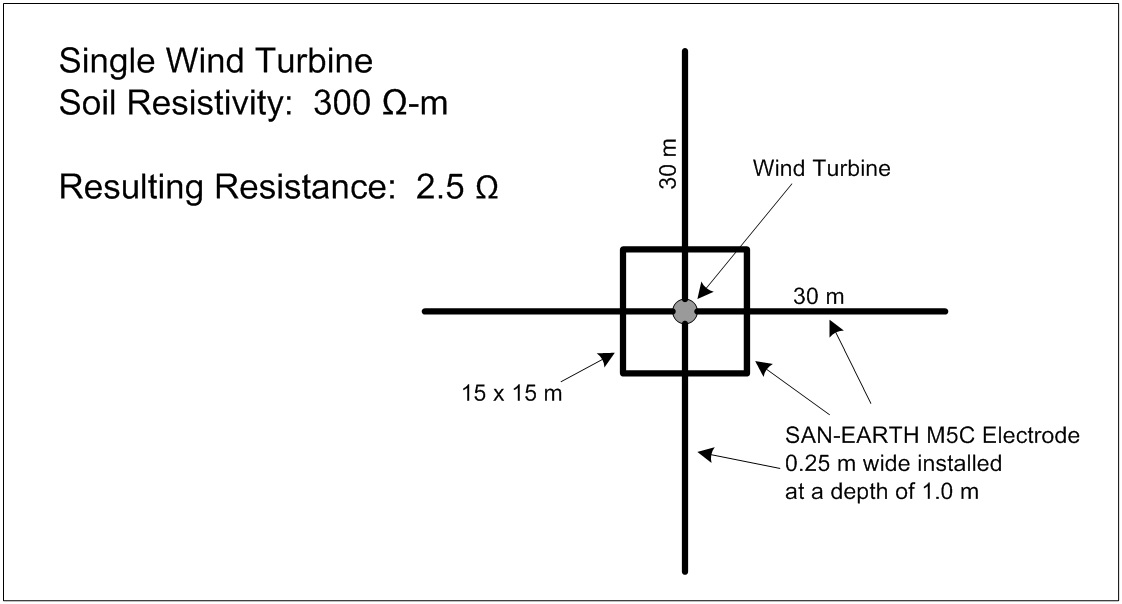

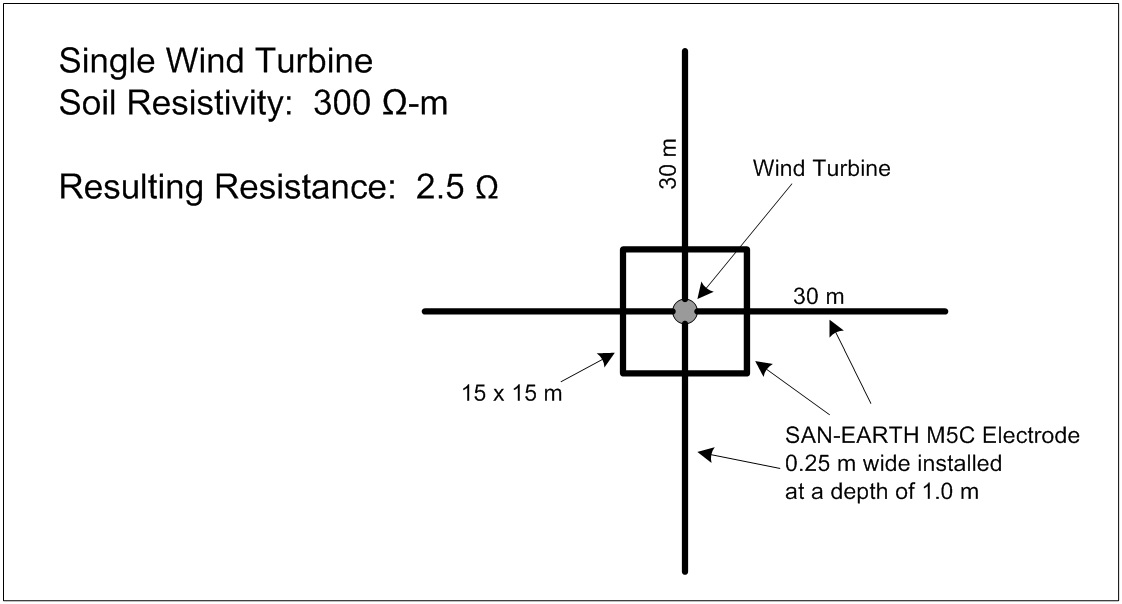

SAN-EARTH conductive cement offers a safe economical long term solution to the windfarm grounding problem. It was specifically developed for locations where resistivity is high and access might be difficult. The typical recommended design for a SAN-EARTH electrode system for a single wind turbine is shown below. It consists of a perimeter ground totaling 60 m (197 ft.) in length combined with four radial electrodes 30 m (98 ft.) each in length and yields a resistance value of 2.5 ohms in 300 ohm-meter soil. The SAN-EARTH electrodes are 0.25m (10 inches) wide and installed at a depth of 1 m (39 inches).

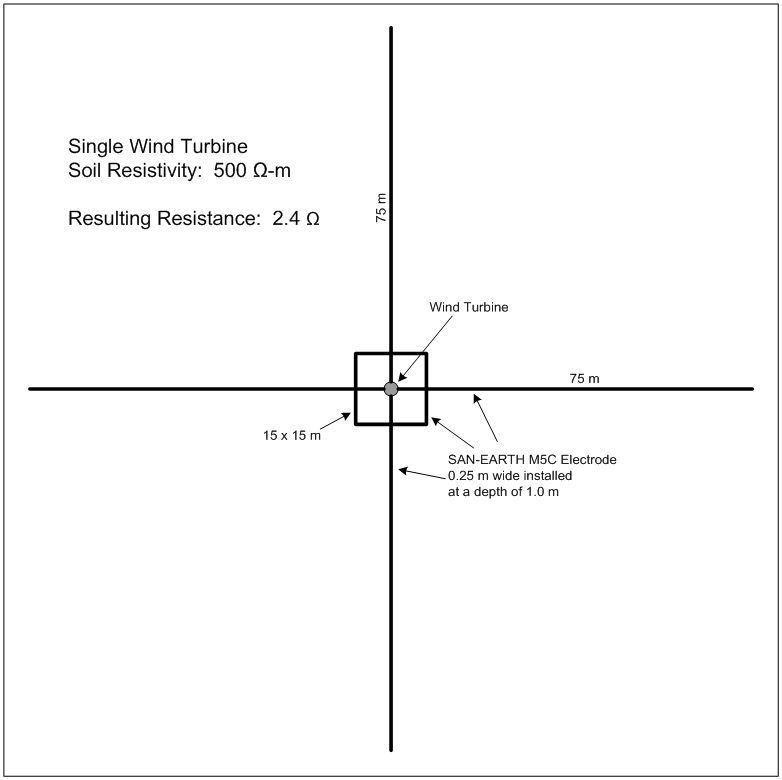

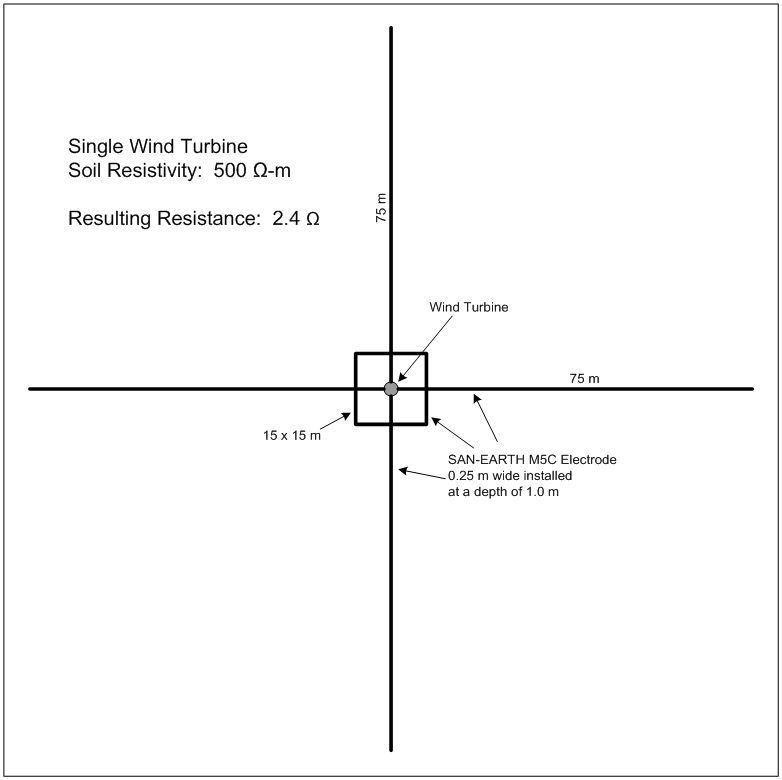

In higher resistivity environments often associated with wind farm installations, similar low resistance values can be achieved by simply increasing the length of the radials. Four 75 m (246 foot) SAN-EARTH radials yield a resistance of 2.4 Ω in a 500 Ω-m resistivity environment. Installation is relatively simple. First, 0.25 m (10 inch) wide trenches are dug to an appropriate depth, one meter in the examples here. SAN-EARTH can be installed as a dry powder or mixed with water and applied as a mortar. The counterpoise wire is placed in the trench so that it is surrounded by the SAN-EARTH material. Over time SAN-EARTH hardens to become a conductive solid. Thus, the surface area of the grounding electrode is greatly increased and lower resistance values are achieved. Corrosion in the counterpoise wire is prevented and conductor theft becomes much more difficult.

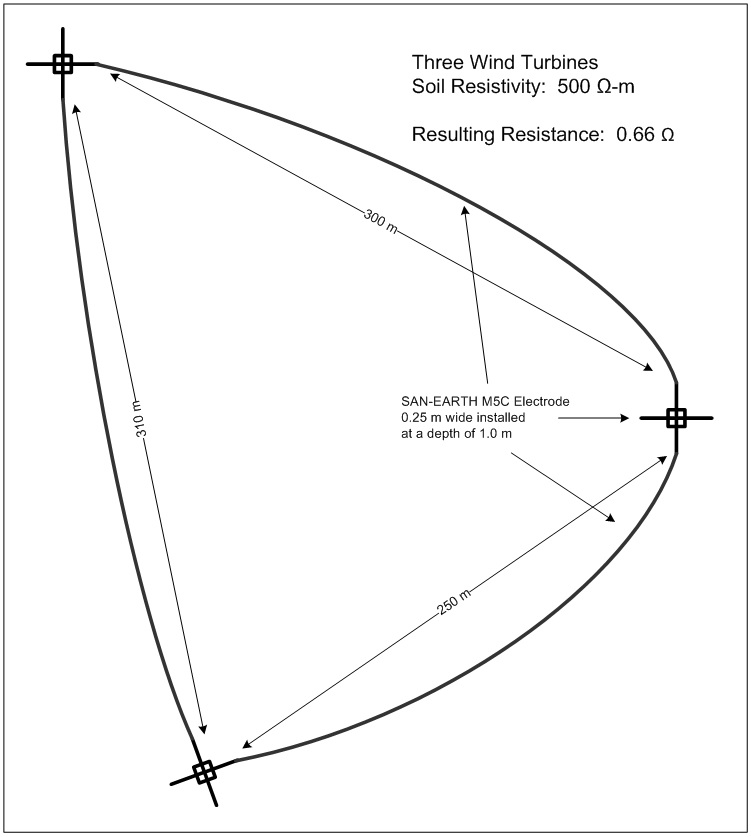

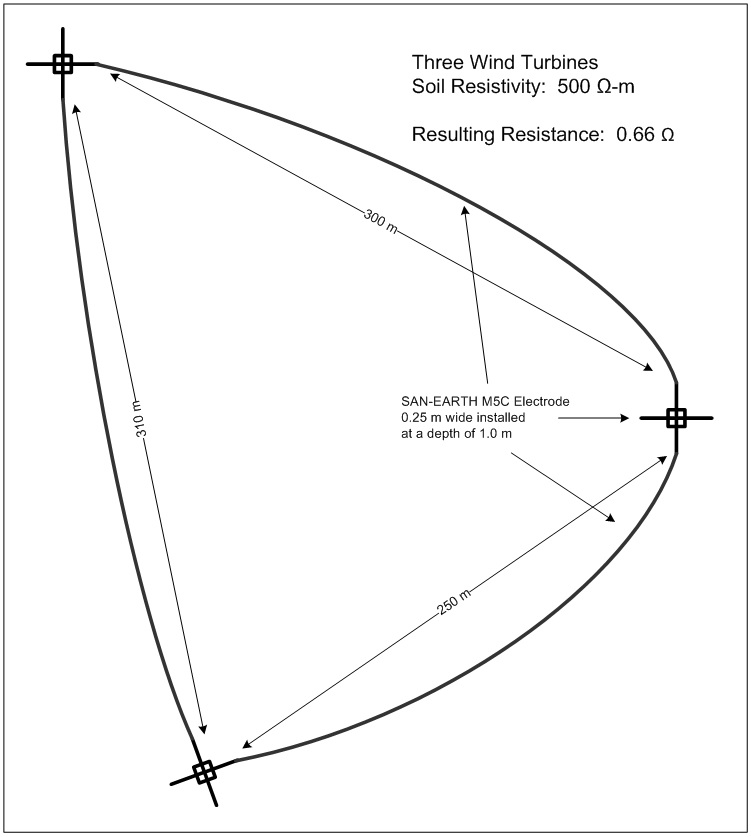

Wind turbines grounded in this way can be connected together to achieve even more dramatic results. In the example below, the grounding electrode systems for three turbines are connected together using the SAN-EARTH design. Vertical ground rods, often difficult to install at wind farm locations, are not needed to achieve a consistent low resistance connection to earth. Wind turbines grounded in this way can be connected together to achieve even more dramatic results. In the example below, the grounding electrode systems for three turbines are connected together using the SAN-EARTH design. Vertical ground rods, often difficult to install at wind farm locations, are not needed to achieve a consistent low resistance connection to earth.

Wind turbine grounding systems must be designed so that excessive overvoltages are prevented and potential gradients that may cause damage to equipment or threaten human life are eliminated. With SAN-EARTH, that goal can be achieved easily and economically.

Grounding resistance and soil resistivity are, by definition, always proportional. Knowing that, we can see that the system above would yield a resistance value of 1.32 Ω in a 1,000 Ω-m resistivity environment. Even if the resistivity went as high as 3,000 Ω-m, this design would produce a resistance value below 4 Ω.

Manufactured in the U.S.A., SAN-EARTH is ideal for use in areas where soil resistivity is high. SAN-EARTH reduces construction costs and produces long term consistent results. It is environmentally safe and conforms to IEC Standard 62561-7

|

/* Navigation Bar Contents */

/* Navigation Bar Contents */

Wind turbines grounded in this way can be connected together to achieve even more dramatic results. In the example below, the grounding electrode systems for three turbines are connected together using the SAN-EARTH design. Vertical ground rods, often difficult to install at wind farm locations, are not needed to achieve a consistent low resistance connection to earth.

Wind turbines grounded in this way can be connected together to achieve even more dramatic results. In the example below, the grounding electrode systems for three turbines are connected together using the SAN-EARTH design. Vertical ground rods, often difficult to install at wind farm locations, are not needed to achieve a consistent low resistance connection to earth.